Understanding the Cost Factors Behind Nitrogen Compressor Pricing

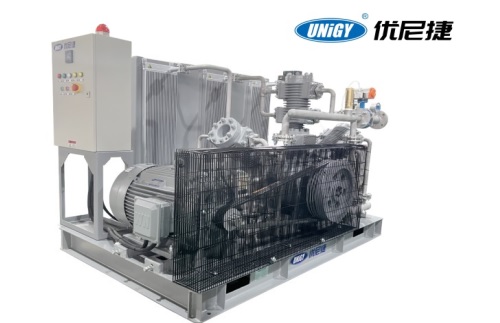

When evaluating industrial equipment investments, understanding nitrogen compressor pricing is essential for procurement teams and facility managers. A nitrogen compressor is a specialized type of gas compressor designed to handle pure nitrogen—a non-reactive, inert gas widely used in chemical processing, electronics manufacturing, food packaging, and oil & gas applications. Unlike standard air compressors, nitrogen compressors must meet stringent purity, pressure, and material compatibility requirements, which directly influence their cost structure.

According to a 2023 market analysis by Grand View Research, the global industrial gas compressor market, which includes nitrogen-specific units, is projected to grow at a CAGR of 4.8% through 2030. This growth reflects increasing demand across sectors requiring high-purity nitrogen delivery systems. However, prices for nitrogen compressors can vary significantly—from approximately 15,000forsmall−scale,low−pressureunitstoover250,000 for large, multi-stage, oil-free reciprocating or diaphragm compressors used in semiconductor fabrication.

Several key factors determine nitrogen compressor pricing. First is the compression technology employed. Reciprocating compressors are common for high-pressure applications (up to 5,000 psi), while screw or scroll compressors may be used for lower-pressure continuous flow scenarios. Oil-lubricated models are generally less expensive but risk nitrogen contamination; thus, oil-free designs—often using PTFE or carbon-based piston rings—are preferred in sensitive industries, albeit at a 20–35% premium.

Material selection also impacts cost. For instance, compressors handling ultra-high-purity nitrogen in pharmaceutical settings often feature 316L stainless steel cylinders and valves to prevent particulate shedding or corrosion. In contrast, standard industrial units may use cast iron or carbon steel, reducing upfront expenses but limiting application scope.

Another cost driver is certification and compliance. Units destined for use in hazardous environments (e.g., offshore platforms) must meet ATEX, IECEx, or API 618 standards, requiring additional engineering validation and safety features such as explosion-proof motors or leak detection systems. These certifications can add 10–25% to the base price.

Energy efficiency further influences long-term value. The U.S. Department of Energy notes that compressors account for nearly 10% of total industrial electricity consumption. High-efficiency nitrogen compressors with variable speed drives (VSDs) may carry a higher initial price but reduce operational costs by 15–35% over a 10-year lifecycle.

Finally, geographic location and after-sales support affect pricing. Manufacturers in Europe and North America typically offer robust service networks and longer warranties, justifying higher list prices compared to Asian OEMs. However, total cost of ownership—including maintenance intervals, spare part availability, and technical support responsiveness—should guide purchasing decisions more than upfront cost alone.

As industries continue to prioritize process reliability and gas purity, nitrogen compressor pricing will remain closely tied to performance specifications, material integrity, and regulatory adherence. Buyers are encouraged to conduct lifecycle cost analyses rather than focus solely on acquisition price, ensuring optimal return on investment in critical gas handling infrastructure.