How to maintain a twin screw air compressor

-

1. Regularly detect the radial displacement of the screw rotor

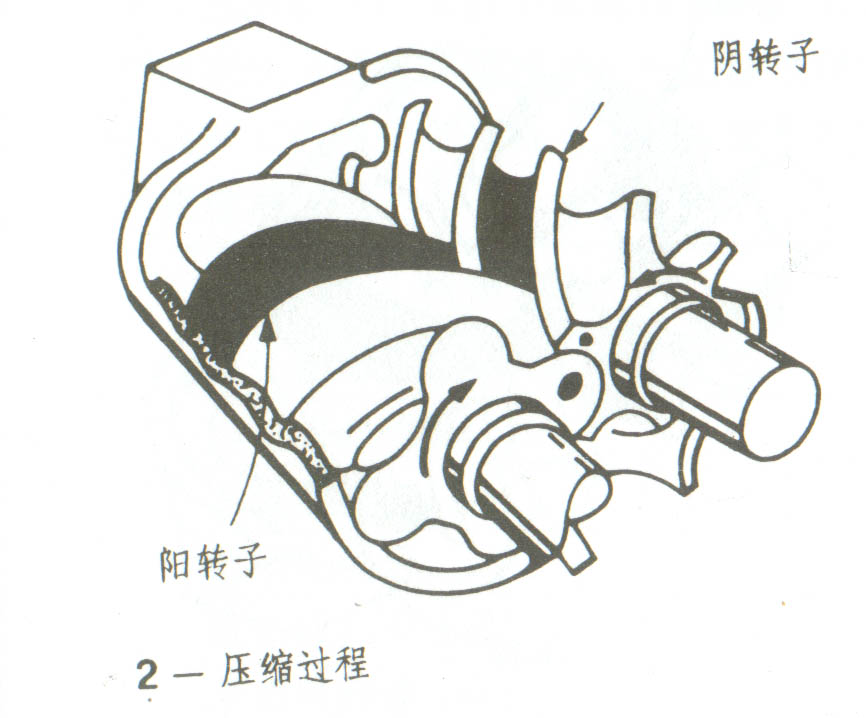

According to the equipment structure, both oil injection screw and oil-free screw air compressors are composed of a pair of male and female rotors and the external surface of the head housing, forming a working chamber. The male and female rotors of the oil injection screw compressor use main and driven gears, while the oil-free screw uses synchronous gears. Due to the small gap between the male and female rotors and between the rotor and the object, excessive radial displacement can damage the rotor and the external surface of the housing, Even after correction, it will affect the inspection of the air compressor and cause a lot of useless work.

2. The air compressor box should be sealed for use

In summer, UNI90-160 and UNI5-55 usually open the box cover according to heat dissipation needs. After consulting experts, it was found that the flow direction of the box cooling air duct is a specific plan. Although opening the box door can reduce the external temperature of some components, this operation undermines the overall ventilation plan of the unit and has a poor effect.

3. Strictly require the use of specialized oil filter libraries

The oil filter for the smooth oil of the air compressor is specially made, with an O-ring seal and compression spring at the oil inlet. There is a special low oil pressure safety valve inside the special oil filter, which can ensure the smooth demand of the unit after tripping when the oil pressure is too low. This is particularly important for oil injected screw compressors.

4. Strictly adhere to the use of smooth oil

The oil-free screw air compressor has a long service life for smooth oil, with an oil change cycle of about two years or continuous operation of 12000 hours; Oil injection twin screw air compressor, approximately 4000-8000h. Regularly analyze the water content in smooth oil, and when the water content is high, it is necessary to replace it all. When replacing smooth oil, the oil should be completely drained, and the machine head, oil tank, oil cooler, oil filter, and oil cut-off valve should all have drain plugs. Before draining the oil, ensure that the machine is running for a period of time to ensure oil temperature.

5. Motor greasing

When adding grease to the motor, it is necessary to ensure that it is carried out under stable load and constant speed; Oil free machine, 20g of grease per end every 2000h, fuel injection machine, 75g of grease per end every 2000h.

6. Shutdown

For oil-free machines, shutdown operation is particularly important. Before stopping, it is necessary to open the manual drain valve of the middle and rear coolers to completely drain the condensate water, and then press the "unload" button to ensure that the unit operates at 10% load for 20 minutes, completely drying the moisture on the surface of the rotor (the rotor surface is covered with a layer of tetrafluoroethylene protective sleeve).

7. Strictly prevent rotor reversal

Reverse rotation of the rotor will reduce the amount of smooth fuel injection, causing the male and female rotors to bite, causing the rotor to experience reverse force and friction between the end of the rotor and the outer surface of the machine head housing.

Unijie provides customers with industrial equipment such as screw air compressors, oil-free compressors, nitrogen compressors, sulfur hexafluoride (SF6) compressors, helium compressors, medium and high pressure air compressors. We not only provide customers with air compressors, but also provide solutions for oil-free compressed gas systems.

- 1、定期检测螺杆转子径向位移

- 根据设备结构,喷油螺杆和无油螺杆空压机,都是由一对阴阳转子与机头壳体内外表组成工作腔,喷油螺杆压缩机的阴阳转子运用的是主、从动齿轮,无油螺杆运用的是同步齿轮,因为阴阳转子之间和转子与客体之间空隙较小,径向位移过大会损坏转子以及壳体内外表,即使修正后也会影响空压机审察,作较多的无用功。

- 2、空压机箱体要密封运用

- 夏日通常根据散热需求,UNI90-160和UNI5-55都是翻开箱体盖板。通过咨询专家,箱体冷却风道规划流向都是特定规划,翻开箱门虽然能降低部分组件的外表温度,但这种操作破坏了机组的全体通风规划,作用较差。

- 3、严格要求运用特制油滤文库

- 空压机光滑油的油滤是特殊制作的,油进口是一个O形环密封和压紧弹簧,而专用油滤内部有一个特制的油压低安全阀,当油压过低时,可以确保机组跳机后的光滑需求,对喷油螺杆压缩机特别重要。

- 4、严格遵守光滑油运用

- 无油螺杆空压机,光滑油运用期限较长,换油周期大约两年或接连运行12000h;喷油双螺杆空压机,约4000~8000h。定期剖析光滑油中的水含量,含水较高时,有必要全部替换。替换光滑油时,排油要完全,机头、油槽、油冷器、油滤器、断油阀都有排净丝堵,排油前要确保机作运行一段时间,确保油温。

- 5、电机加脂

- 电机加脂时,有必要确保在稳定负荷、恒定转速下进行;无油机,每2000h每端加脂20g,喷油机,每2000h每端加脂75g。

- 6、停机

- 对无油机,停机操作特别重要,停机前有必要翻开中后冷却器手动排水阀,完全排放冷凝水,然后按“卸载”按钮,确保机组10%负荷下运行20min,完全吹干转子外表的水分(转子外表是一层四氟乙烯保护套)。

- 7、严格防止转子反转

- 转子反转会削减光滑喷油量,使阴阳转子咬死,一起使转子受力反向,转子末端同机头壳体内外表摩擦。

- 优尼捷为客户提供螺杆空压机,无油压缩机,氮气压缩机,六氟化硫(sf6)压缩机,氦气压缩机,中高压空气压缩机等工业设备,我们不止为客户提供空压机,更为客户提供无油压缩气体系统解决方案。